Top

TopReducing the Environmental Impact of Our Business

Reducing the environmental impact of business activities is a social responsibility for companies that must be fulfilled in order to realize a sustainable society as well as an important measure for achieving sustainable growth. Accordingly, we are striving to reduce greenhouse gas (GHG) emissions and waste, effectively use energy and resources, and develop environmentally friendly and safe products.

Initiatives to Address Climate Change

Based on international frameworks, such as the United Nations Sustainable Development Goals and the Paris Agreement, Terumo recognizes that reducing GHG emissions from its business activities, through means such as improving energy efficiency and combating climate change, is an important responsibility and is advancing Group-wide activities to this end.

Companies are now expected to set science-based GHG emission reduction targets and to work toward the achievement of these targets in order to contribute to accomplishing the Paris Agreement’s goal. Terumo has established the Group’s new target of GHG emission reduction for fiscal 2030 based on the methodology for setting GHG emission reduction target endorsed by the international initiative known as Science Based Targets. The Scope 1* and 2* target was re-approved by the Science-Based Targets initiative in March 2023, and the 2030 target was increased from a 30% reduction compared to 2018 to a 50.4% reduction, with an update from the ‘well-below 2 degrees pathway’ to the ‘1.5 degrees pathway’, which was certified in 2020. In addition, the Terumo Group aims to achieve carbon neutrality by 2040 and sets a target for the proportion of renewable energy used.

Terumo Group’s target of GHG emission reduction

Scope 1* and 2*

- Reduce absolute GHG emissions 50.4% by 2030 from a 2018 base year

- Increase a ratio of renewable electricity use up to 50% by 2030

- Achieve carbon neutrality by 2040

Scope 3*

- Reduce GHG emissions 60% per unit of revenue by 2030 from a 2018 base year

*

Scope 1: Direct GHG emissions by the company (e.g. fuel combustion)

*

Scope 2: Electricity indirect GHG emissions (e.g. GHG emissions from electric companies)

*

Scope 3: Other indirect GHG emissions (e.g. production of purchased materials, transportation, and waste disposal)

Press Release

Development of Environmentally Friendly and Safe Products

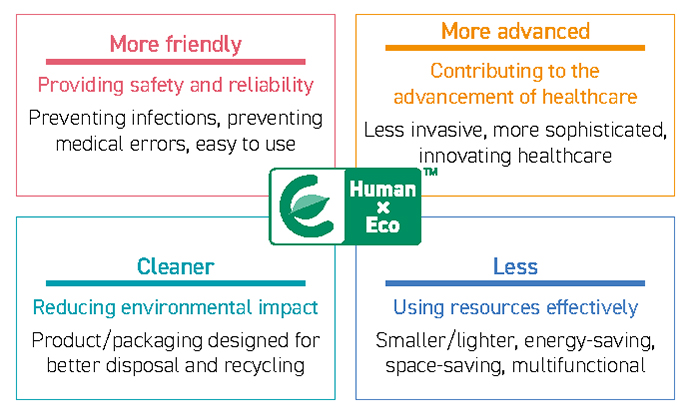

Terumo has established and applied to product development its proprietary Human×Eco Development Guidelines, a set of guidelines for developing products that are friendly to both people and the environment. Products that exhibit excellence with regard to the guidelines display the “Human×Eco” logo, an internalcertification mark, to make this excellence readily apparent to customers.

Human×Eco Development Guidelines

Examples of Human×Eco Certified Products

Infusion Pump—Resource Conservation and Improved Usability

An infusion pump is a medical device that administers an intravenous solution (IV) etc. at a specified flow rate. By comparison with conventional devices, this product is around 40% lighter. This makes it easier to carry around, and it is also expected to make a positive contribution to environmental protection through resource conservation and enhanced delivery efficiency. Furthermore, the use of a color LCD display makes the display easier to read, and the provision of a wireless communication function that enables simple transfer of activity record data is expected to contribute toward enhancing the working efficiency of medical professionals.

Intravascular Ultrasound Catheter—Shortened Examination Times and Improved Efficiency

Intravascular ultrasound catheters are used when performing intravascular ultrasounds, an examination technique thatutilizes ultrasonic waves to observe the inside of blood vessels. By improving the image resolution, image acquisition, and processing speeds, and ease of operation of our catheters, we have helped reduce the amount of time required for preparations, examinations, and image interpretation pertaining to intravascular ultrasounds. We anticipate that the shorter procedure times will reduce the burden on patients and medical professionals and thereby contribute to the realization of safer and more efficient treatments.

IV (Intravenous) Solution Bag— Conservation of Resources and Reduction of Waste

TERUPACK Eco is an IV solution bag designed to be environmentally friendly. It is manufactured with less plastic, in a production process that consumes less energy and emits less CO2 than previous processes. In addition, because TERUPACK Eco bags weigh 23% less than prior bags, we expect them to generate less waste and reduce overall impact on the environment.

TRI Introducer Kit—Minimally Invasive and Medically Cost Efficient

Percutaneous coronary intervention (PCI) can be performed by inserting a catheter at either the wrist or the groin. Inserting at the wrist, in a procedure called transradial intervention (TRI), entails fewer complications, such as post-procedure bleeding, and is less invasive. Terumo has developed an innovative introducer kit that features a sheath with a thinner, more finely formed wall for a smaller outside diameter. A narrower sheath makes more treatment options available for patients with small arteries while also reducing costs and resource usage associated with post-procedure complications.

Vaccination Syringe—Conservation of Resources and Reduction of Waste, Timely Development to Meet Medical Demand During the COVID-19 Pandemic In 2021, when vaccination

In 2021, when vaccination against COVID-19 was underway in Japan, there was urgent demand for syringes that could be used for intramuscular injection. To prevent the wasting of precious doses of vaccine, Terumo utilized the technology of its low dead-volume syringes, which were being sold for use in subcutaneous injection, to develop a new syringe with a longer embedded needle (16mm compared to 13mm in existing models) for use in intramuscular injection. This new product obtained pharmaceutical approval as Japan’s first syringe with an embedded needle for intramuscular injection for use with COVID-19 vaccine, and was on sale within three months of development beginning. Having the needle already embedded in the syringe allows more efficient use of the vaccine agent, while also reducing the amount of plastic needed in the manufacturing process.

Closed Infusion Systems—Contributions to Safer, More Efficient Infusion Line Management

Keeping infusion line mixers closed helps to prevent contamination by external airborne microbes. In addition, our infusion line connectors are designed to not retain any liquid and, therefore, can be used to deliver even very small amounts of drug solutions. Even the connection of syringes and infusion devices requiresno special adapters, so drug solution delivery is simple, quick, and more secure from procedural errors. Easy inventory management contributes to greater safety and efficiency in managing infusion line stocks.

Waste Reduction and Recycling

As part of its efforts to use resources more efficiently, Terumo sets targets for recycling and for reducing final disposal waste. From a safety perspective, it is difficult to reuse waste (i.e., practice material recycling) internally. We do, however, strive to reduce the amount of plastic and metal waste generated in manufacturing processes and from business activities in offices. In addition, we segregate various types of waste from such processes and activities, and, with the cooperation of a recycling company, turn it into plastic products, refuse plastic fuel (RPF), and organic fertilizer.

Initiatives to Realize the Circular Economy

Terumo is implementing initiatives to help realize the circular economy, in response to the issues of resource depletion and climate change. To drive the development of new products that are both user-friendly and environmentally-friendly, we have formulated our own unique set of standards—the Human × Eco Development Guidelines (see p. 42 for more details). Based on the guidelines, we are proceeding with efforts to control the amount of waste generated in production processes, choose materials and components that have a small environmental impact, and make both products and packaging smaller and more lightweight.

Ensuring that plastic and other by-products that are produced during the manufacturing process are properly sorted and transferred to recycling firms to create new resources, we are implementing material recycling that recycles waste into new plastic products such as stationery and pallets. In fiscal 2023, we began to sell our first products that are partly made from recycled plastic, in a first for the Terumo Group.

Pallet made from recycled plastic

Products partly made using recycled plastic

Effective Utilization of Water Resources

Terumo uses large quantities of water in its manufacturing processes and for producing infusion solution. Using the Aqueduct water risk assessment tool developed by the World Resources Institute (WRI), we monitor the risks and opportunities associated with our water usage on a periodic basis, examining the status of water resources, and the level of water stress, etc., in the countries and regions where each of Terumo’s production sites are located. Survey results indicate that, as of the end of fiscal 2022, of Terumo’s 34 production sites, there were sites in the Philippines, China, North America, and Europe that were located in regions with high levels of water stress. . Terumo has set water-related targets, and is promoting efforts to reduce water use (water withdrawal) and realize water recycling. As regards the specific measures being implemented, besides working to control water loss in production processes by installing flow meters to measure water usage for specific purposes and adopting systems that allow effective visualization of water use, we are also proceeding with the adoption of water-saving equipment and the recycling of cooling water, etc.

Initiatives for Biodiversity Conservation

Terumo understands that our lives and health and even the practice of medicine itself depend on the existence of diverse living organisms and ecosystems. As a company whose business draws benefits from nature, Terumo seeks to preserve biodiversity through environmental education and reforestation activities and works to support the development of a society in which humans coexist with nature.

Mt. Fuji Reforestation Project

Terumo has two factories in the city of Fujinomiya in Shizuoka, Japan. Both take in groundwater from springs at the foot of Mt. Fuji for use in the production of medical devices, pharmaceuticals, and other products. Recognizing that our business depends on the use of natural resources, we launched the Terumo Mt. Fuji Reforestation Project in fiscal 2003 with the aim of restoring the natural forests in this area. This project involves the reforestation of parts of Mt. Fuji’s forests where many trees have been destroyed by typhoons. Repopulating these areas with native tree species will help them become more resistant to future natural disasters and ensure that they can continue to serve as a source of groundwater.

In fiscal 2011, three parties—Shizuoka Prefecture, a local forest owner, and Terumo—entered into an agreement called the Shizuoka Mirai-no-Mori (Future Forest) Supporter Pact. Under this agreement, we plant trees and maintain forested areas to create the Terumo Megumi-no-Morireserve within the Fumoto district of Fujinomiya. Moreover, we are engaged in year-round reforestation activities based on the concepts of the environment, living organisms, interaction, and health through this agreement.

ECO Challenge

We hold the ECO Challenge in which volunteer Terumo associates in Japan conduct a variety of voluntary environmental preservation activities at home and at work. In fiscal 2022, about 2,900 people took part in the ECO Challenge, undertaking seven energysaving and resource-conservation activities that will contribute toward reducing CO2 emissions, as well as a carbon neutrality education program. Points were calculated based on the results of participating associates, and Terumo translated these points into a monetary value for donations to the Children’s Forest Program (The Philippines) and the Coastal Forest Restoration Project in Tohoku Region arranged by the Organization for industrial, Spiritual and Cultural Advancement — International, Japan (OISCA Japan).

Initiatives at overseas business sites

Besides Terumo’s initiatives in Japan, the Terumo Group’s overseas business sites have also been holding special events to strengthen awareness of the importance of recycling, and implementing initiatives to safeguard biodiversity through tree-planting. In fiscal 2022, efforts to reduce the impact on the environment through forest conservation and environmental education included a treeplanting activity conducted by Terumo (Philippines) Corporation in the Caliraya-Lumot Watershed forest conservation area in the Province of Laguna, and a Family Day activity organized by Terumo Vietnam Co., Ltd. , in which over 1,000 people from more than 300 families took part, with participants making toys from recycled materials.

For details, please refer to our Terumo Report [Environment].